Update April 2020:

Repairs officially started on 1 April. In my mind, I attempted to try and plan a sequence of events, mostly focusing on the mechanical side first and then progressing towards the bodywork side of things.

First up, was to look at the radiator fan. After removing it from the Ute, I noticed that one of the arms of the housing was cracked. Thankfully there was little / no movement on this arm, so I reckoned some good old Pratley Steel would come in useful now. (I shudder to think what the cost of a new fan housing would be, also because you cannot find these things used anywhere! (I'm lucky to have a spare in storage should I ever need it in future).

Some pics of the crack:

View attachment 7

View attachment 8

And some pics after the repair, strong and functional (if not the prettiest):

View attachment 9

Also, with the fan removed, I could inspect the other side of the radiator. As is to be expected, it's taken a hit from the pressure, and the fan housing has squashed the fins a bit:

View attachment 1

I had previously noted that the turbo also took a hit, more specifically the wastegate actuator. This wasn't going to work well, and I was a bit concerned that it actually damaged the wastegate arm itself. The only way to find out would be to remove the actuator. This is a much easier job now with everything removed out the way, and in no time it was stripped off. Thankfully, the wastegate arm is still ok and opens and closes as it should without any resistance. Yay (no turbo spares required).

Next step was to straighten the actuator rod. I used some mild panelbeating skills, and a bunch of nuts so as not to damage the threads. Before and after pics below:

View attachment 2

View attachment 3

Success. I then reinstalled this onto the turbo. while I was busy with that, I noticed that my O2 sensor in the downpipe was a bit loose (must be from vibrations), so I nipped that up as well. Job done.

A few days later, I was ready to tackle the intercooler. There was the 1 obvious hit which may have been a potential boost leak, as well as straightening of some fins here and there. Also, the cooler had a good 8 years of dirt and grime build up on it, so after removing, I first gave it a thorough clean, using a combination of Prepsol, steel wool and sponges.

Also note the oil buildup in the cooler. This is from when the turbo seals failed previously (this buildup would also occur if any oil breather pipes are plumbed into the induction (mine aren't - they go to the oil catch can).

View attachment 4

After a good couple of hours squinting up close and personal with the cooler, I had straightened up the fins as best as I could, and it looks so much better after the clean as well:

View attachment 5

When I was cleaning the cooler as well, I filled it with water, sealed off the ends and added some air pressure. Pleased to report that there are no leaks from anywhere. When I was straightening the fins, I just added some Pratley Steel to the damaged spot for just in case...

View attachment 6

I also got round to cleaning and polishing the boost pipes and clamps, so that they are ready for reinstall at a later stage:

View attachment 7

3-5 April:

Next up, to repair the broken radiator bracket from the RHS. This is a cast piece, but conveniently it's only got 3 sides, and 'hollow' to some degree. So I thought I would have a go at making a bit of a splint for it, and then using my trusty Pratley Steel again. An 8mm piece of threaded bar was sacrificed to make the splint, and it all turned out rather well I think (probably stronger than it was before):

View attachment 8

View attachment 9

Next up, to look at the front cradle / slam tray / valance. The RHS was a bit wonky, and from the hit, it had also pushed slightly on the tag on the chassis leg where the slam tray attaches to. Initially I had thought that it was the fender, but the tag is on the chassis leg itself.

Removing the old bits off:

View attachment 1

And here are pics of the RHS and LHS tags on the chassis legs, you will notice that the gap on the RHS is wider than the LHS:

View attachment 2

View attachment 3

I set about doing some DIY panelbeating, starting off with massaging the RHS tag upwards and forwards to close the gap a bit. This took quite a bit of time, but I wanted to do it slowly and make sure that I didn't cause any other issues. Eventually I got it right.

Then came a huge, annoying PITA job. When I bought my spares, the 2 headlights I got were different brands. I didn't think too much of it because I did inspect them visually and from the front the look identical. For the most part, even the back housings are pretty much the same. I was wrong. The RHS headlight had a stupid moulding which interferes directly on the closest spot where it meets the valance. I couldn't modify the housing, so I had to apply some panelbeating skills to the valance itself to free up some room so that the headlight could fit properly. This took an even bigger amount of time, I probably spent 3-4hrs on this doing it bit by bit. Anyways, got it done and the headlights fit properly.

I then moved onto the new bonnet. My intention was to make sure everything fits, before proceeding with prep for painting etc. So with some help I managed to install the bonnet on the hinges. Everything lined up good, but some adjustments would be necessary.

View attachment 4

I then thought about installing the mounting pins for my bonnet struts, but working upside down was a mission, as I had to drill some access holes in the crash structures in order to fit a locking nut onto the pins. So the bonnet came off again, fitted the pins in the space of 30mins, and then refitted the bonnet for another test, note in this picture I tried fitting the original LHS section of the valance, but there were some issues with alignment with the centre section, so I eventually ended up using all 3 sections of the new front valance.

View attachment 5

Things were progressing nicely, and I was now comfortable to begin with the next phase of the repairs: prep for painting....

7-12 April:

To be honest, painting the panels had be a bit worried. I have not actually painted any body panels on a car previously, but knowing I had some equipment at home, I decided to take a chance. Worst case, it looks completely crap and I would need to send it to a panelbeater anyway. (Not sure if I did mention it previously, but before lockdown I went to my local panelbeater who's done work on my cars before, and they actually turned me away, saying they don't paint supplied panels because it impacts on their profit margin as they can't source the parts themselves. I was a bit amused with this, but if that's what floats your boat, then so be it. I'd love to see their attitude now after all this lockdown nonsense, I don't think any business will be in a position to turn away work. Anyway... I digress).

Before lockdown, I managed to get some paint mixed up, and also purchased clear coat and some body filler (in case I needed it). At home I've got a baby compressor, and a brand new spray gun which I purchased from the previous house owner when we moved in. It didn't have any brand on it, so I assume it's a generic piece, and not a professional gun by any means. But... I was keen to try.

After a few hours of Youtube in the evenings, and consulting with a forumite who's done this before, I was ready to commence. I planned to do the valance and bumper stiffener as my first attempt, as these do not need to be perfectly finished, and will be relatively hidden from sight most of the time.

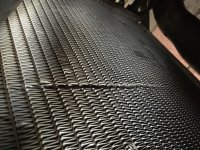

First steps were to roughen up the primer paint on the parts, I used an abrasive pad to do this. Once all was done, a wipe down with some acetone / benzyne to remove dust and other debris was done prior to painting.

View attachment 6

Onto the paint itself, the paint shop told me the silver was ready to go. I decided to add a splash of thinners just in case, as the paint did feel quite thick. I did about 2 coats of silver on these parts and that sat to dry for a few hours. Once dry, I did about 2 coats of clear over the top. Overall, my first painting attempt was so-so, as I had to learn how the gun and compressor work best 'on the fly'. Some parts came out decently, but other spots I got a fuzzy texture, which points to the paint drying in the air before landing on the parts. (I should probably also point out that this was a proper backyard job, no spray booth etc, and uncontrollable weather conditions, so yes, there was bound to be some dust, wind and other factors contributing to the outcome.

Nevertheless, some pics of the completed parts:

View attachment 7

View attachment 8

View attachment 9

I decided to leave the parts to dry properly in the sun for at least a day before reinstalling. While this was happening, I took the time to give the engine bay a decent clean everywhere (this would also help in tracing that pesky oil leak). A pic of things cleaned up (I didn't spend much time on the radiator as the intentions are to replace it at some point):

View attachment 1

Eventually I was ready to reinstall the painted cradle onto the Ute:

View attachment 2

Next steps... reinstall intercooler and boost pipes, but thats in the next update...