Some very bad news,

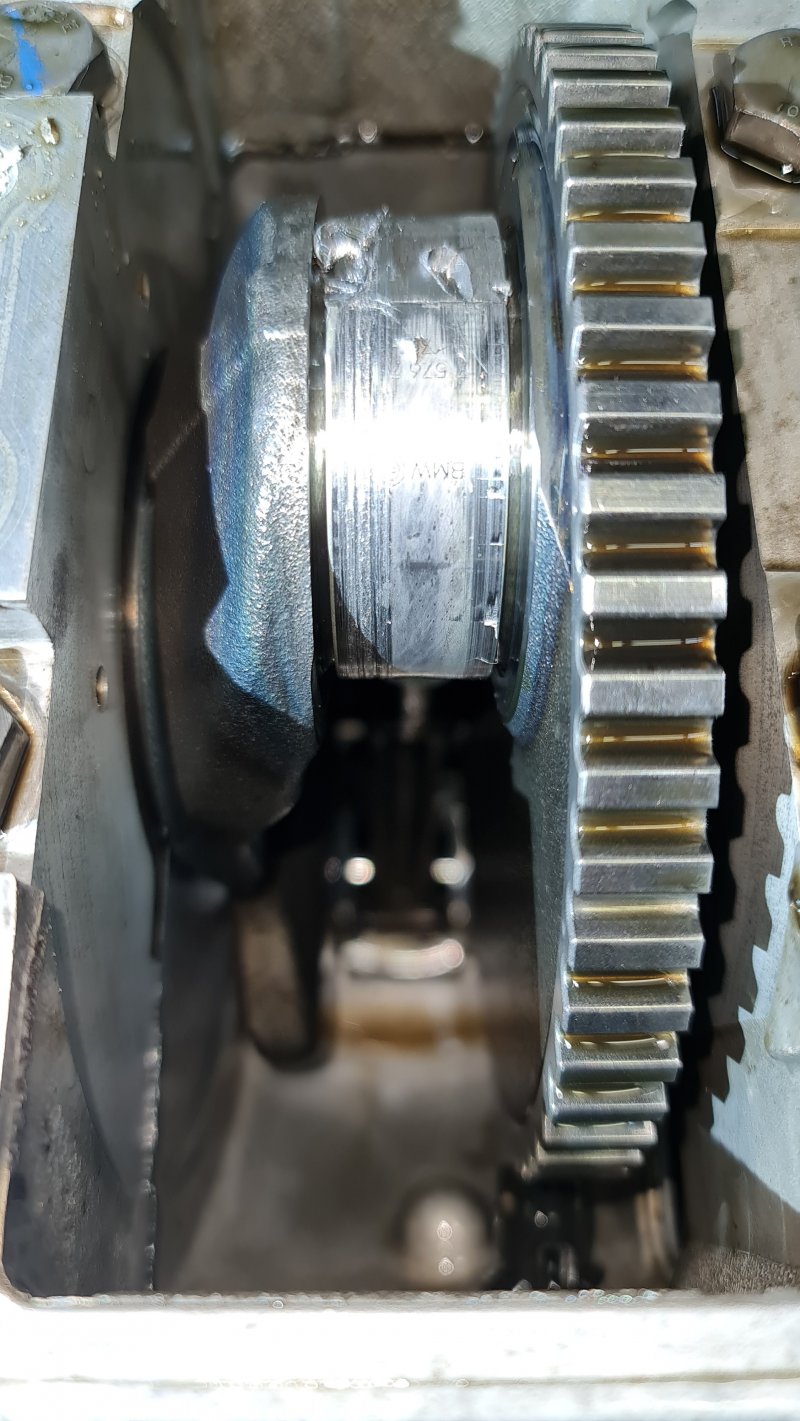

Motor did not last, we did not get to even tune, Cylinder 6 big end seized and all big ends show signs of damage, All other surfaces Mains & Cams are perfect.

I was driving and opened her up to over take +- 10 cars on a open road and when changing from 5th to 6th motor cut out, I luckily did not let the clutch out and just pulled over.

So as you all know the block was imported from the USA, crank was a brand new from BMW all bearings and seals, bolts were OEM from BMW.

Con Rods and oil pump were used from build one (Both were brand new and had done couple of thousand kilometers at the most)

From all the feedback and info received from local and international engine builders, Rod manufacturer, bolt manufacturer the consensus is this is an installation error.

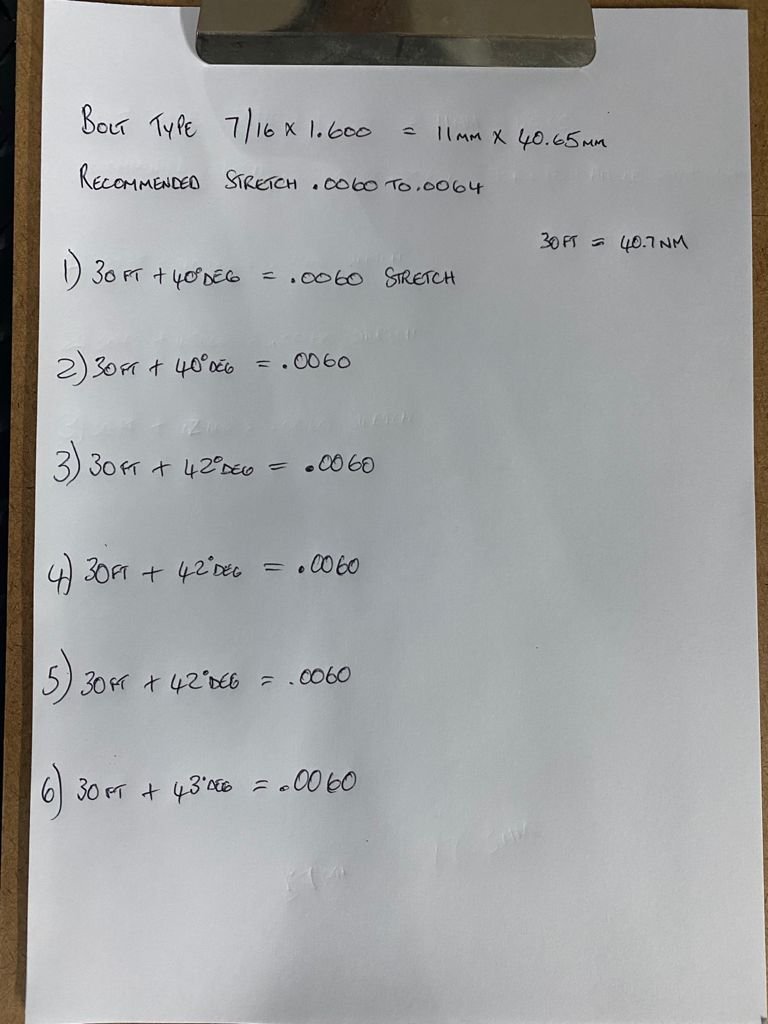

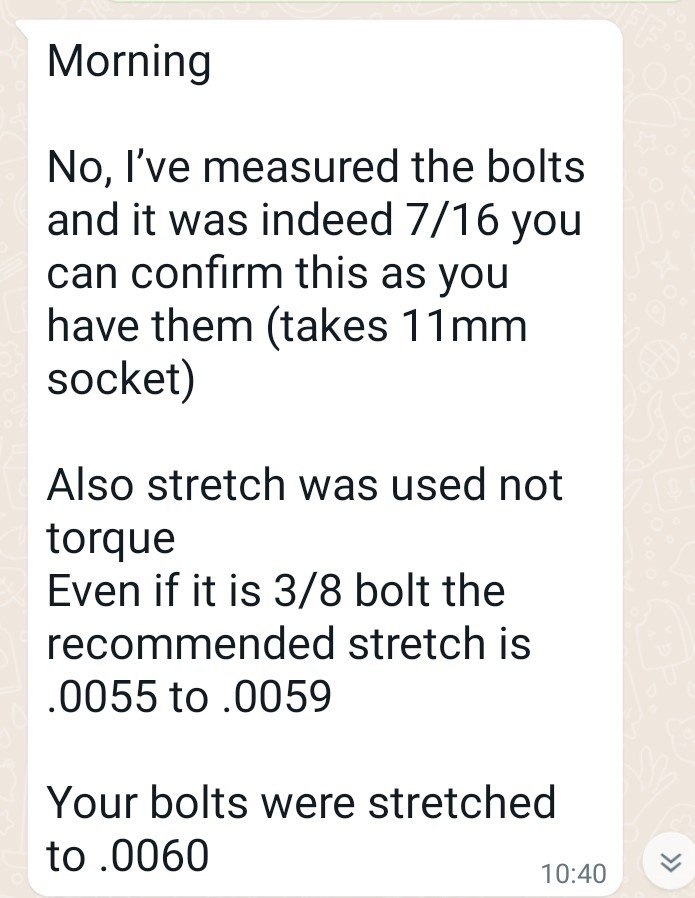

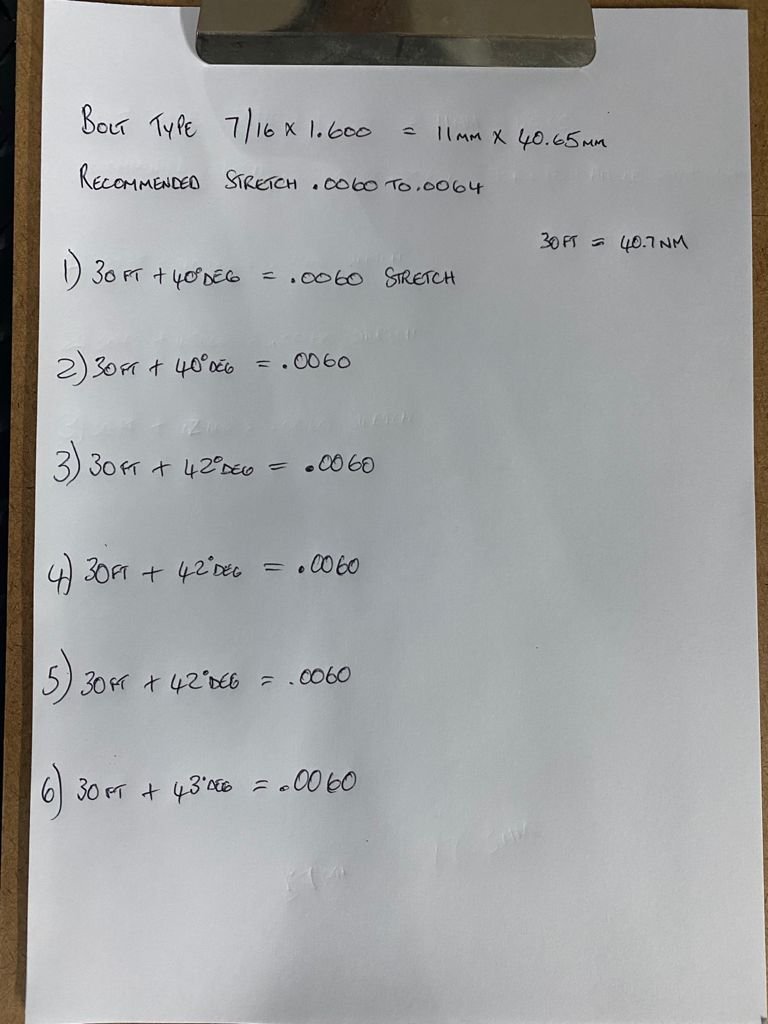

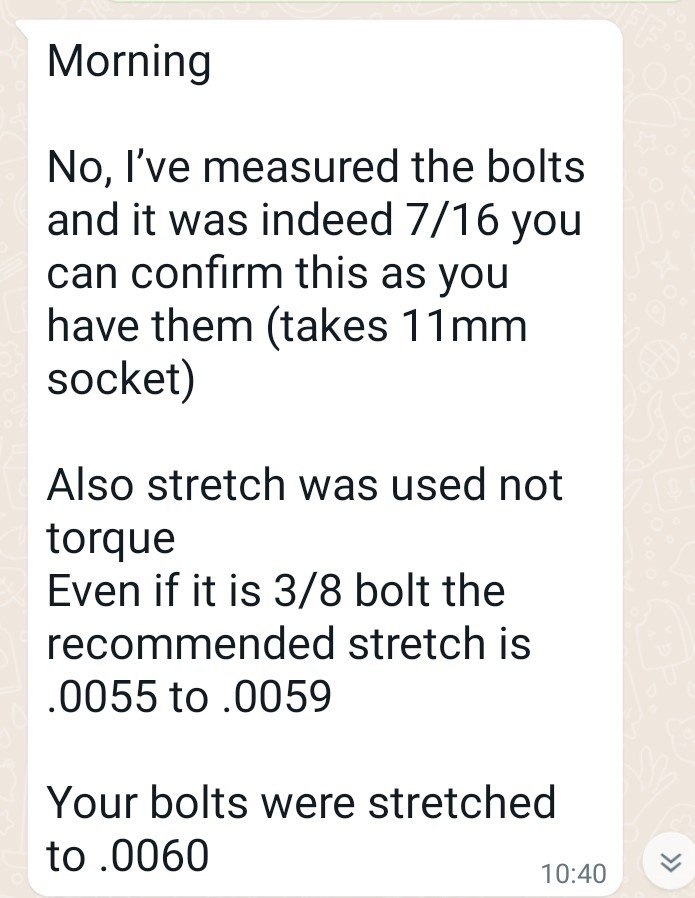

The stretch, torque & angel settings used on rod bolts were for 7/16 x 1.6000" bolt, the rods have 3/8 x 1.6000" the builder insists the bolts were 7/16 because he had to use a 11mm socket (7/16 = 11.13mm) the problem is it is not the head size it is the thickness and length.

The torque is slightly more on the 7/16 and the min stretch of the 7/16 is the max of the 3/8

I consulted various specialist in the field of the rods, Bolts and bearings and they all gave similar feedback.

The company that I got the block from said the clearance claimed (0.05mm) by the builder is not possible on a brand new crank and oem bearings without honing rods or removing material off the crank. (This was not done)

I found plastic gauge on the mains (Not cleaned off) and that is also a no no on a build like this.

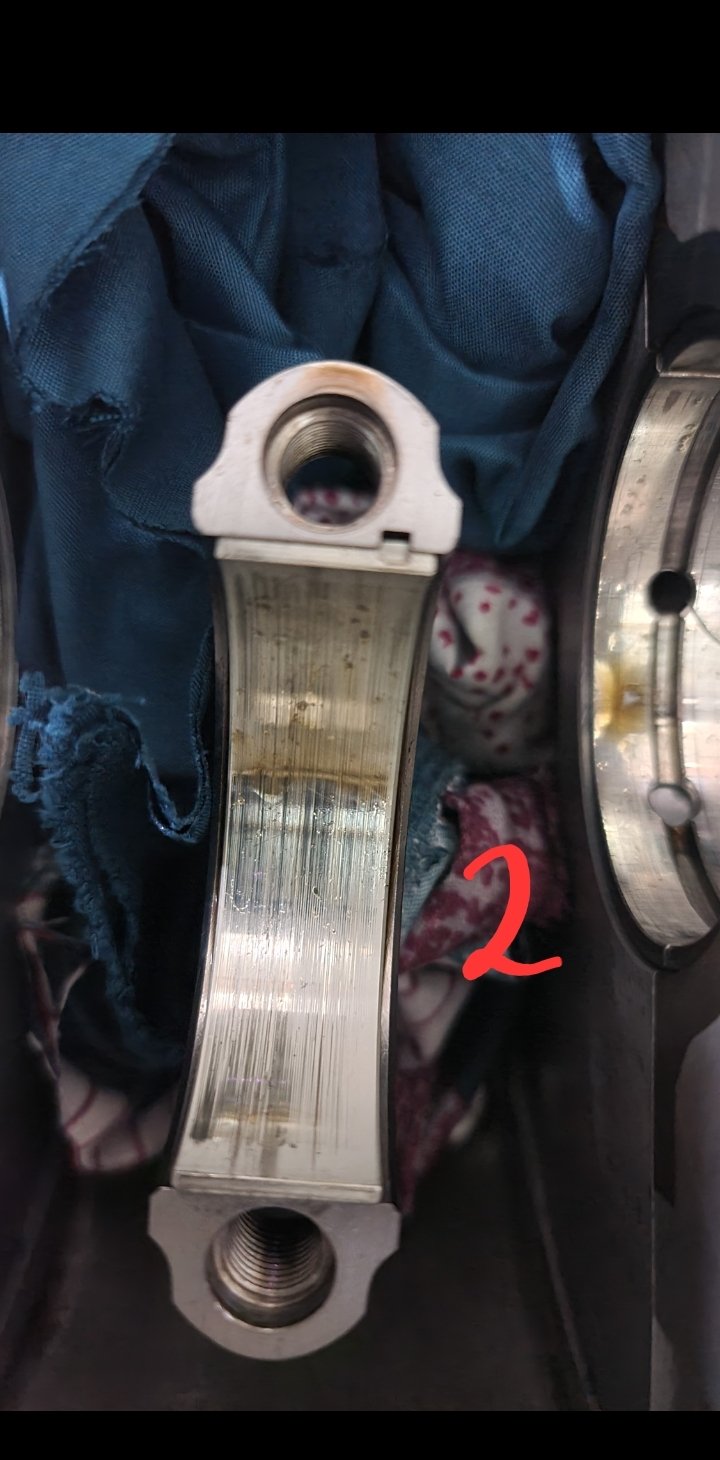

Guys I am gutted, this is a 60k F-up I have been advised to not use the crank if I want to achieve the power I am chasing, I have also been told to replace all rod bolts and check measure rods and replace if out of round (Number 6 must be replaced without question)

So in short only big ends are damaged, so it cannot be oil pump other wise the mains/ and cam Shrafts would show damage.

Incorrect stretch/torques settings used

No metal in filter, only in oil in sump

Oil used Motul 5W 40 V300

when we did the start up procedure we cranked the car without coils & Injectors connected until we had oil pressure on an external oil pressure gauge, after about 2 min of running the yellow oil level light came on, we switched of and put in another 1l when we drained we had 6.5l, car did not have oil cooler connected because we did not want break in oil in the cooler.

Builder is claiming this was the cause of the problem, he did not say anything at the time only once engine broke

we did two break in oil changes (specified by CSS for run in procedure, only a few pieces of dirt in.

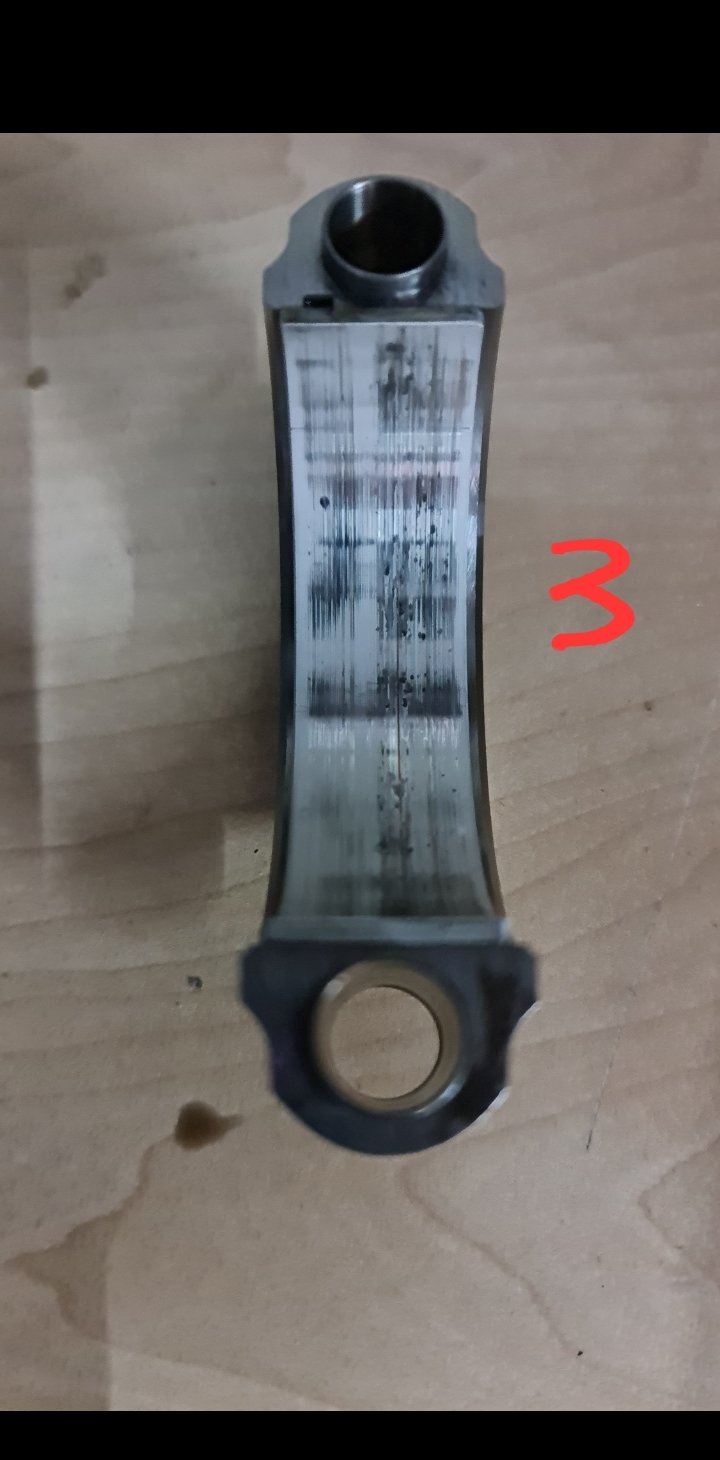

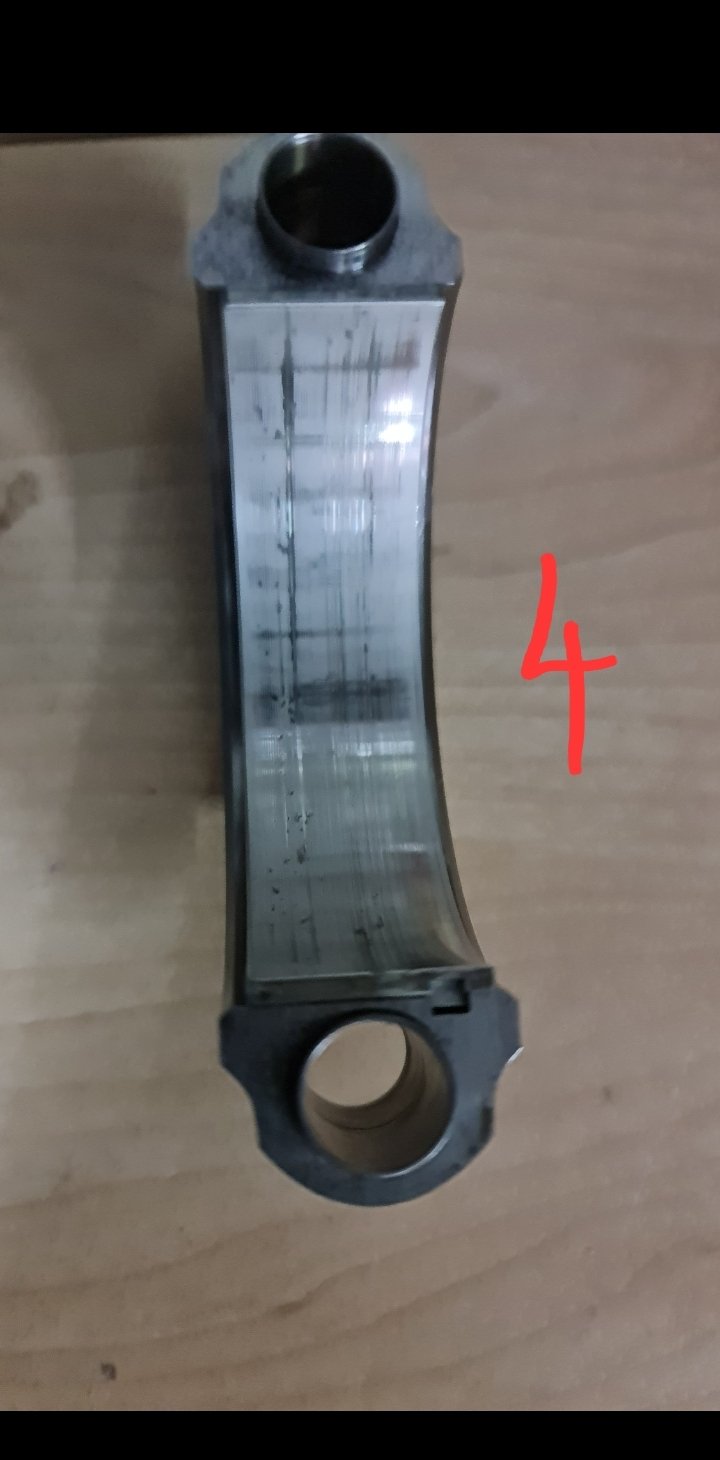

some pics:

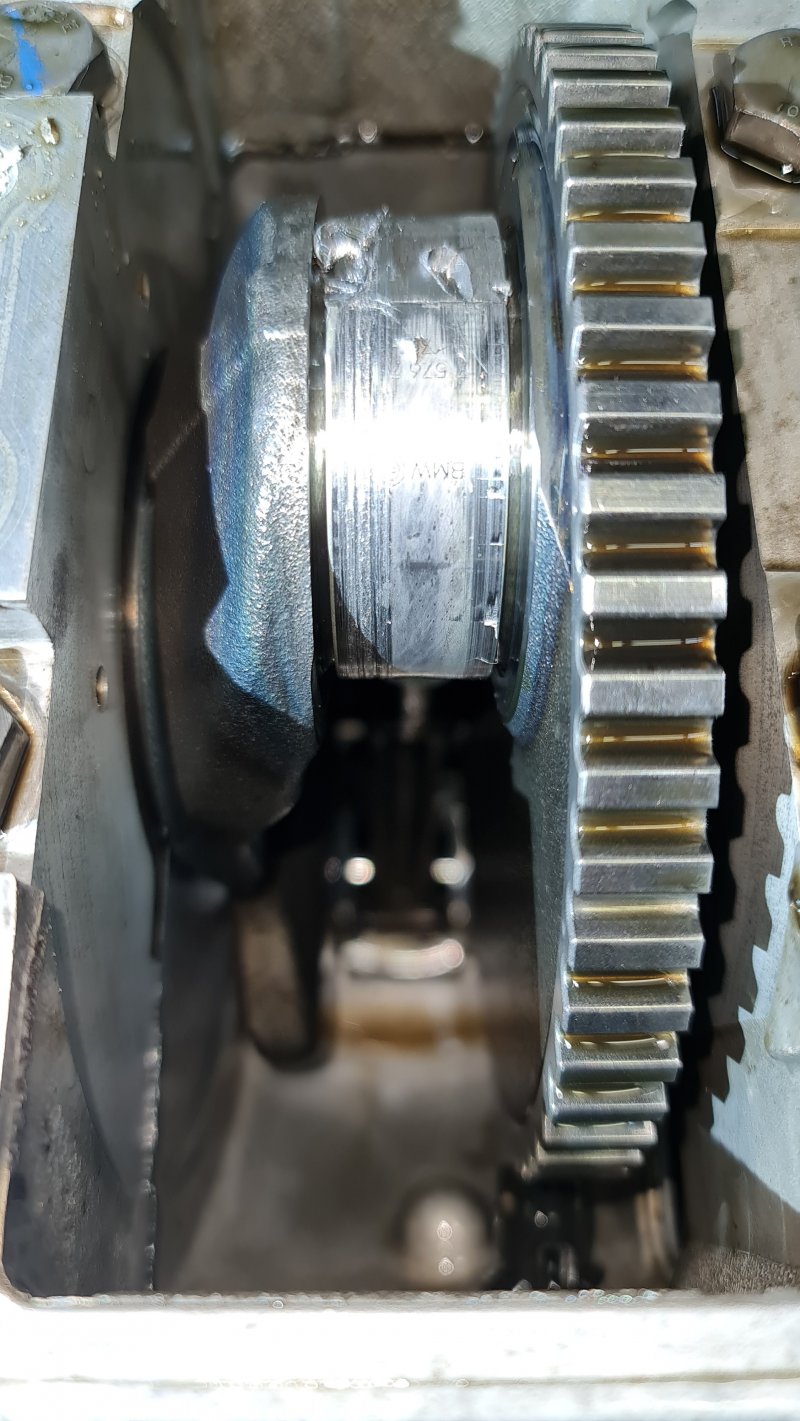

Number 6 Big end (Builder tried to remove with screw driver)

Main between and 6:

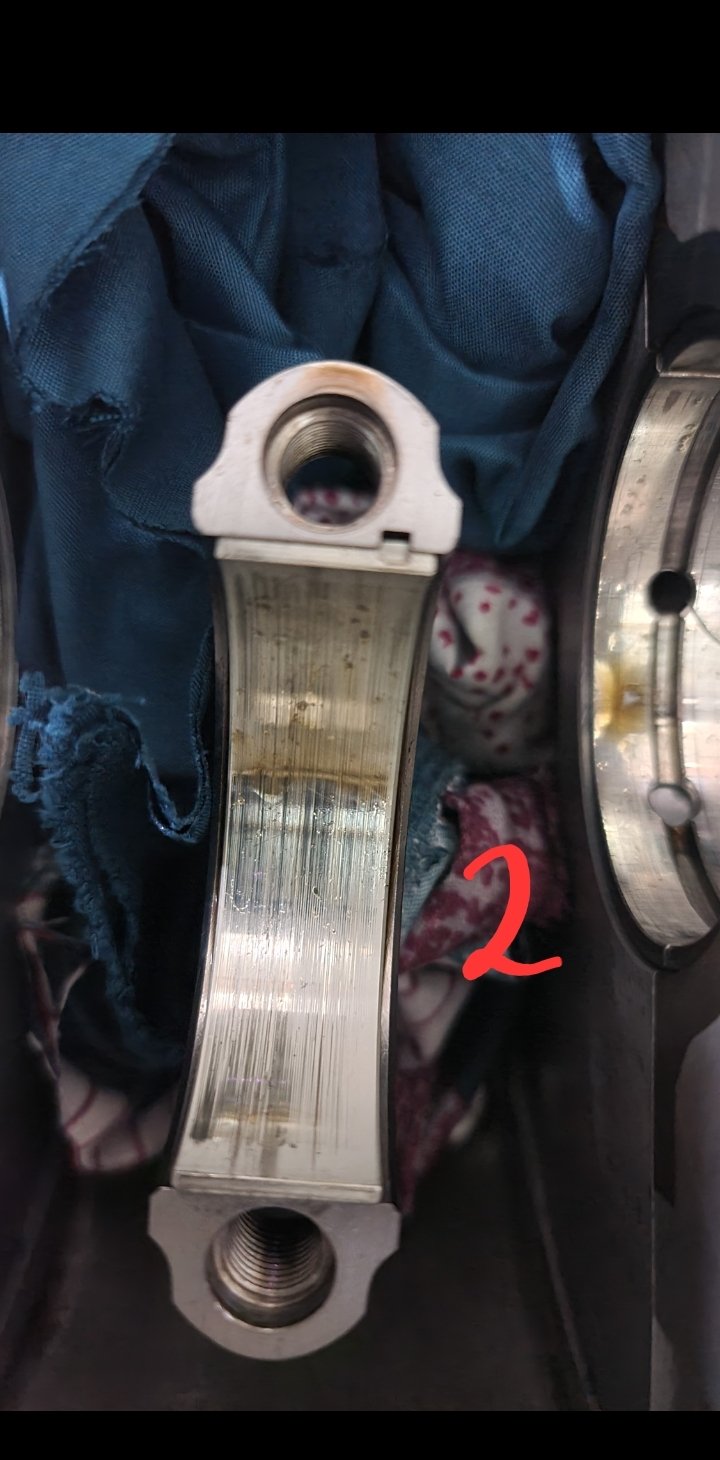

Rod Cap number 6:

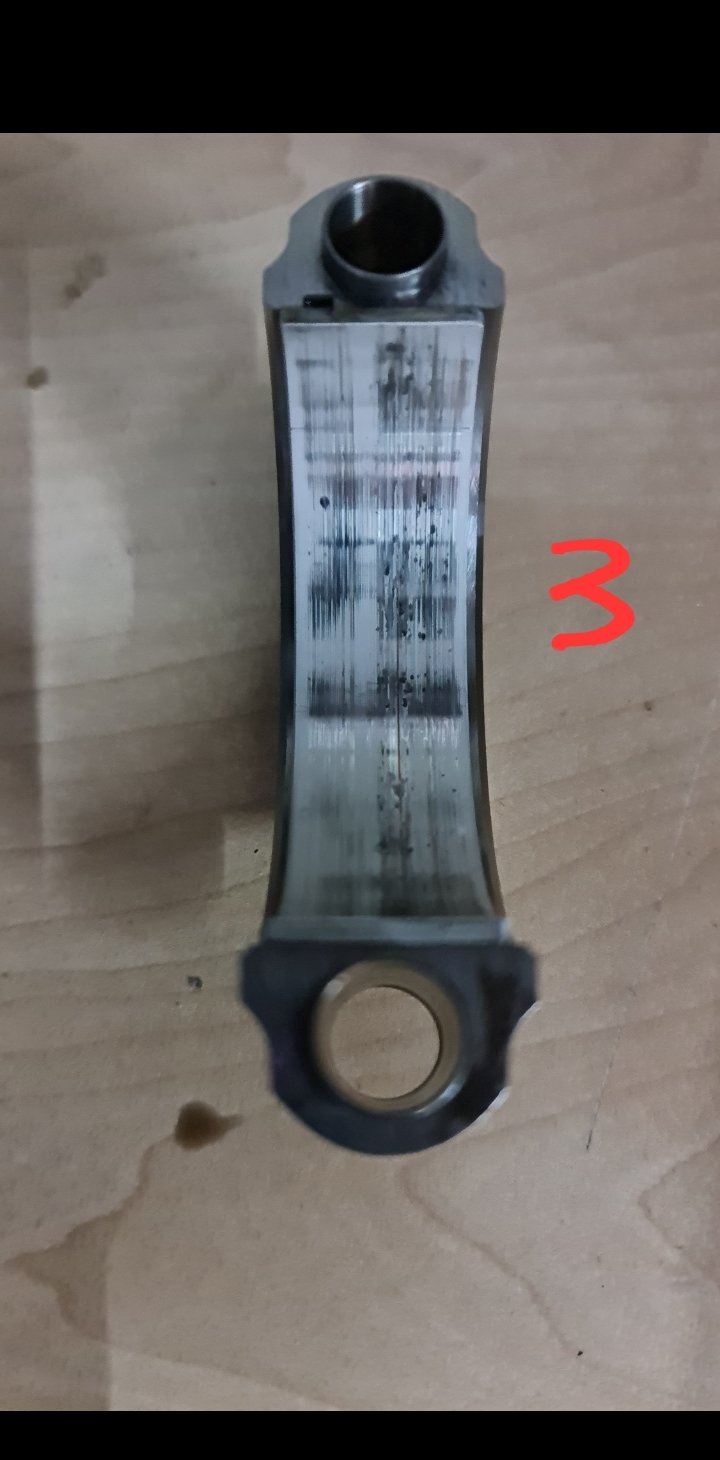

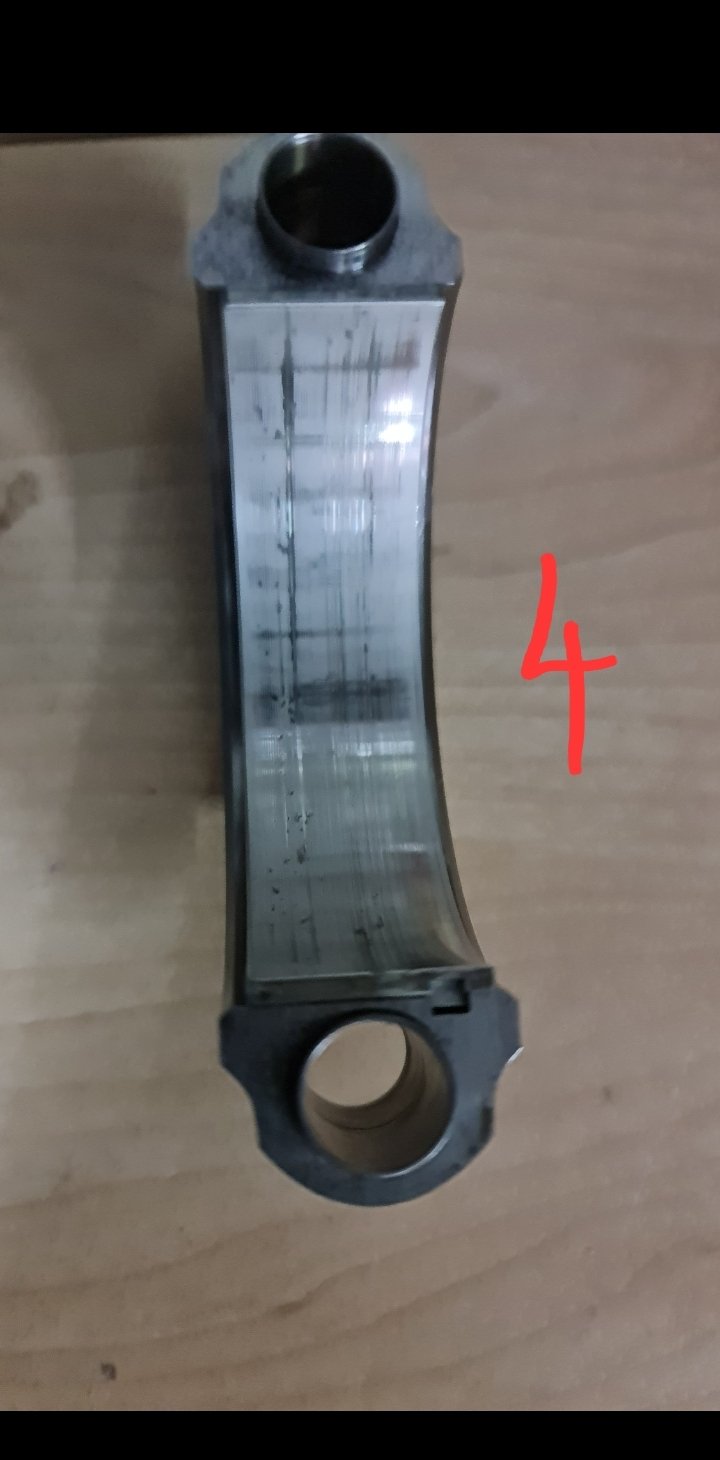

Big ends 1 to 5

torque used:

comment on bolt size to me from builder

I am busy pricing parts I just don't know what to do once I have all parts🤦♂️🤦♂️🤦♂️

Thanks