Hi all.

So an update here which is overdue, and complicated.

Since the last post, i decided to investigate the issue more, and remove the injector completely.

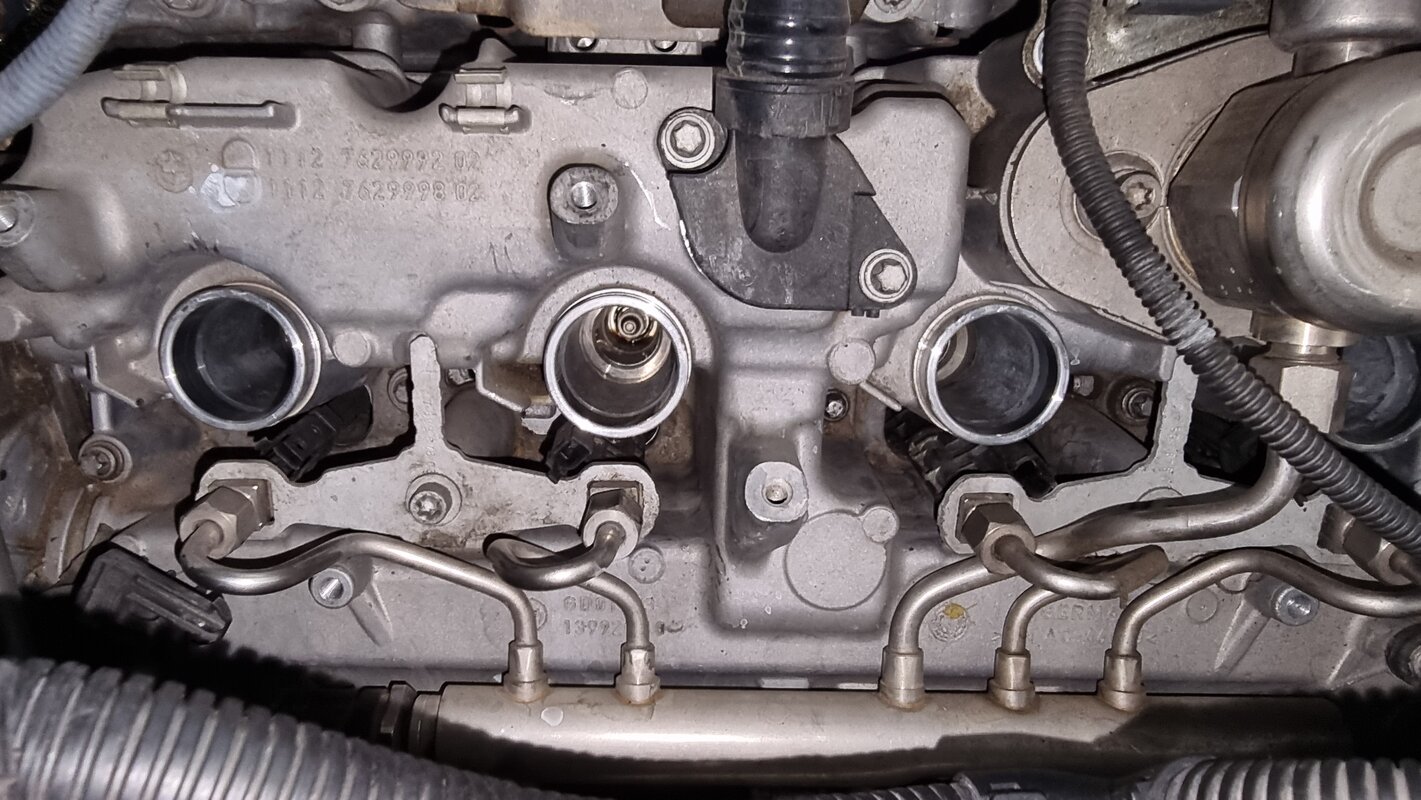

And while doing that, i also decided to pull all the injectors, replace the seals and decouplers, and correctly orientate the injectors, and recode them.

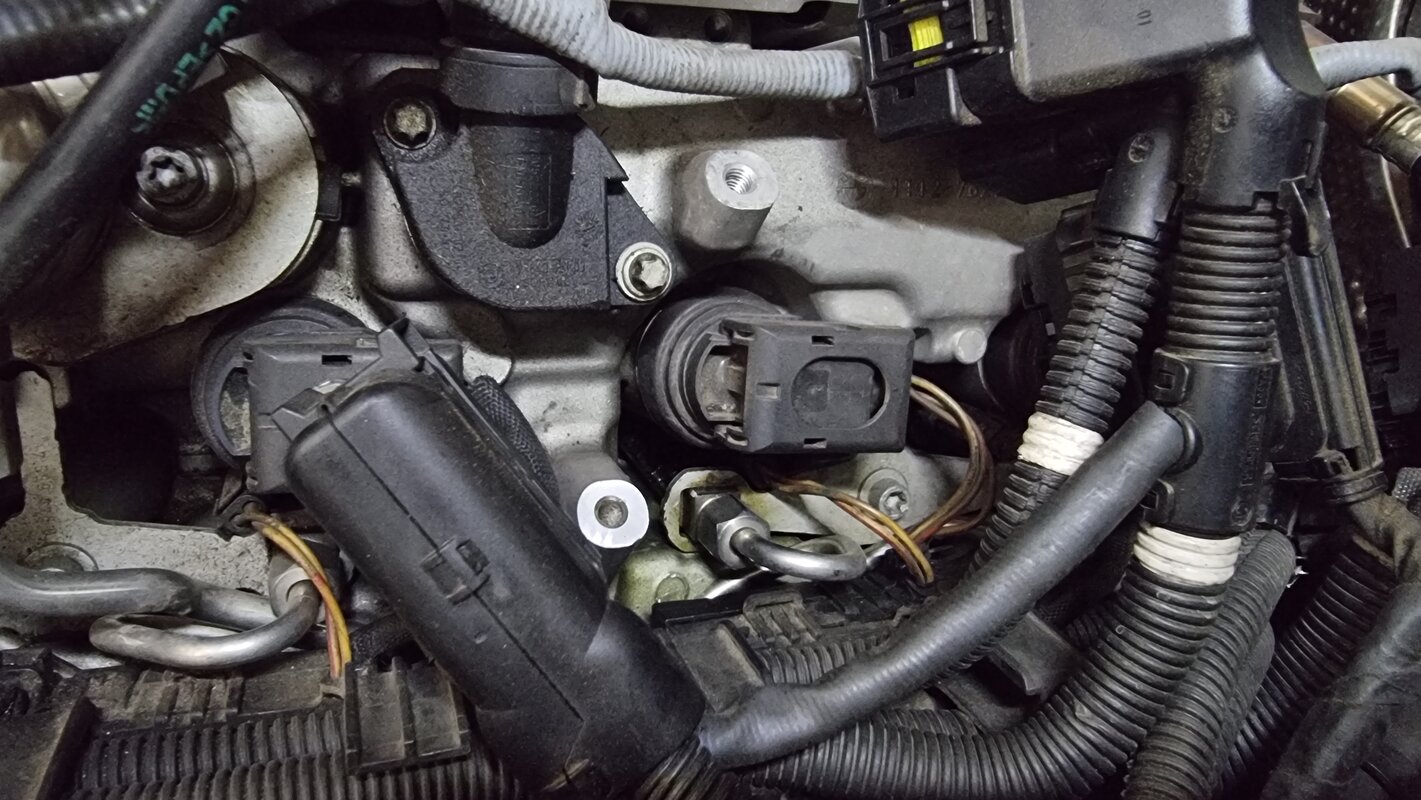

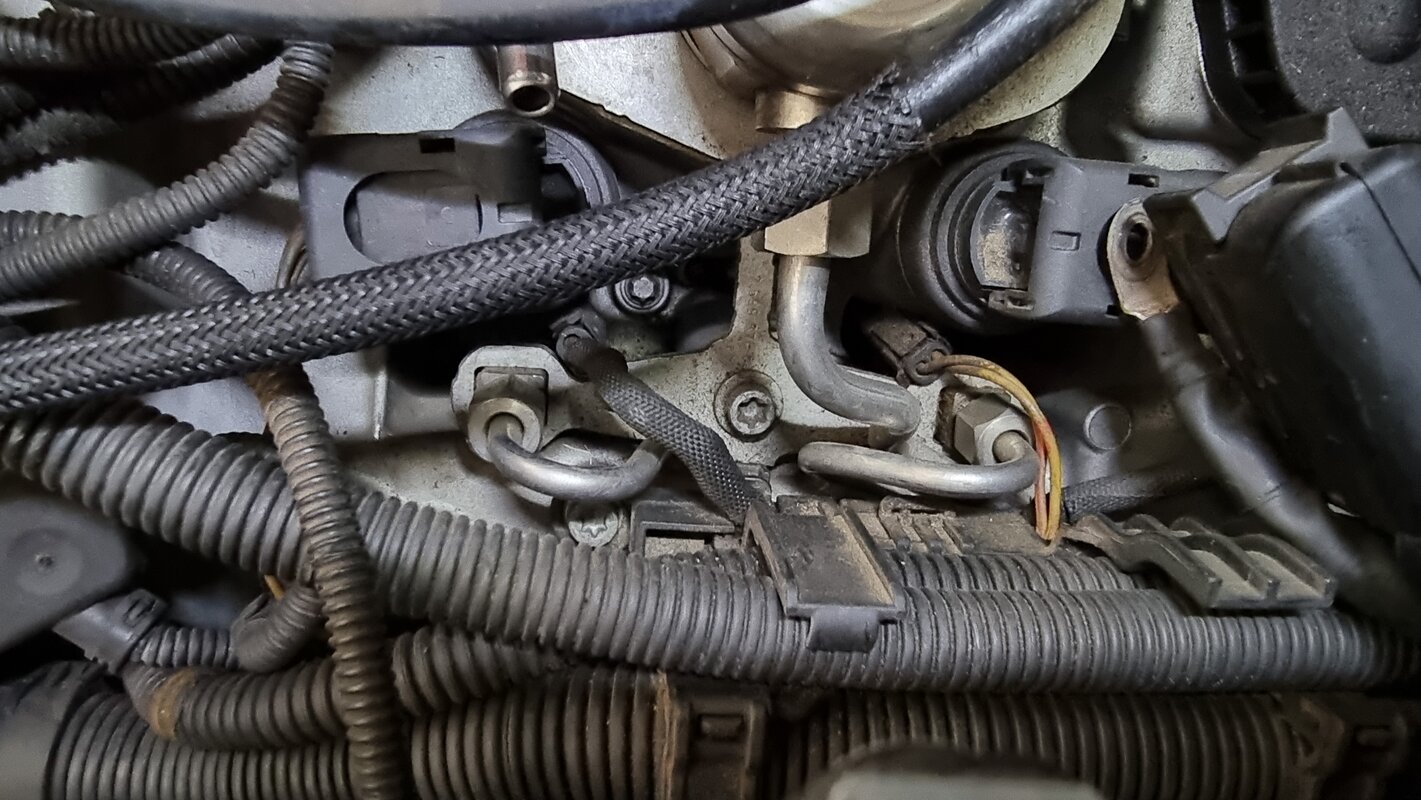

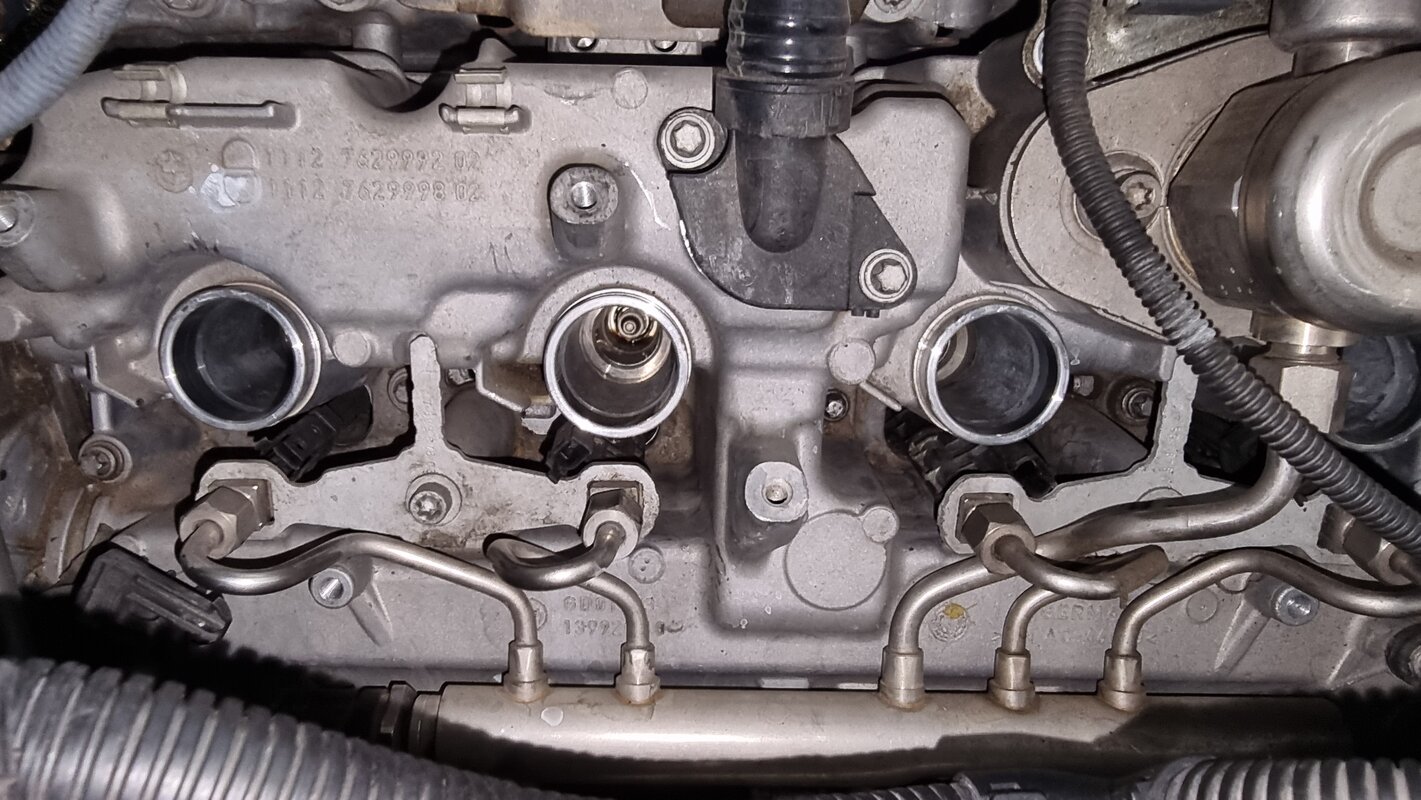

First thing, was strip everything and get to the injectors again, removing the rails on both banks, i wont show pics of the process as thats above.

but to pull the injectors, a special tool is needed, can do it without, but id rather not have taken the chance, so i spoke to JSN BMW, and Viz kindly allowed me to borrow the shops tools, which included the Injector puller, as well as the Seal removal tool.

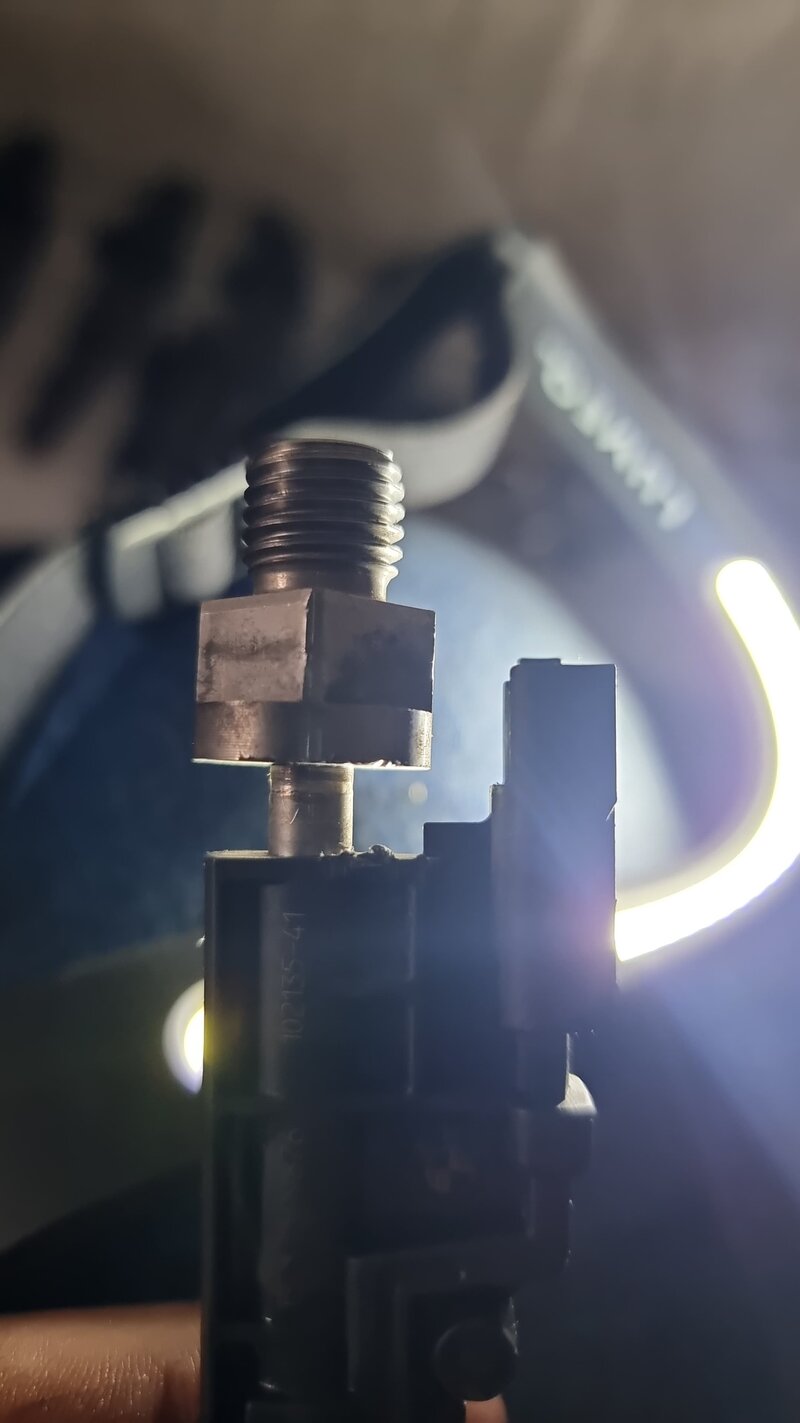

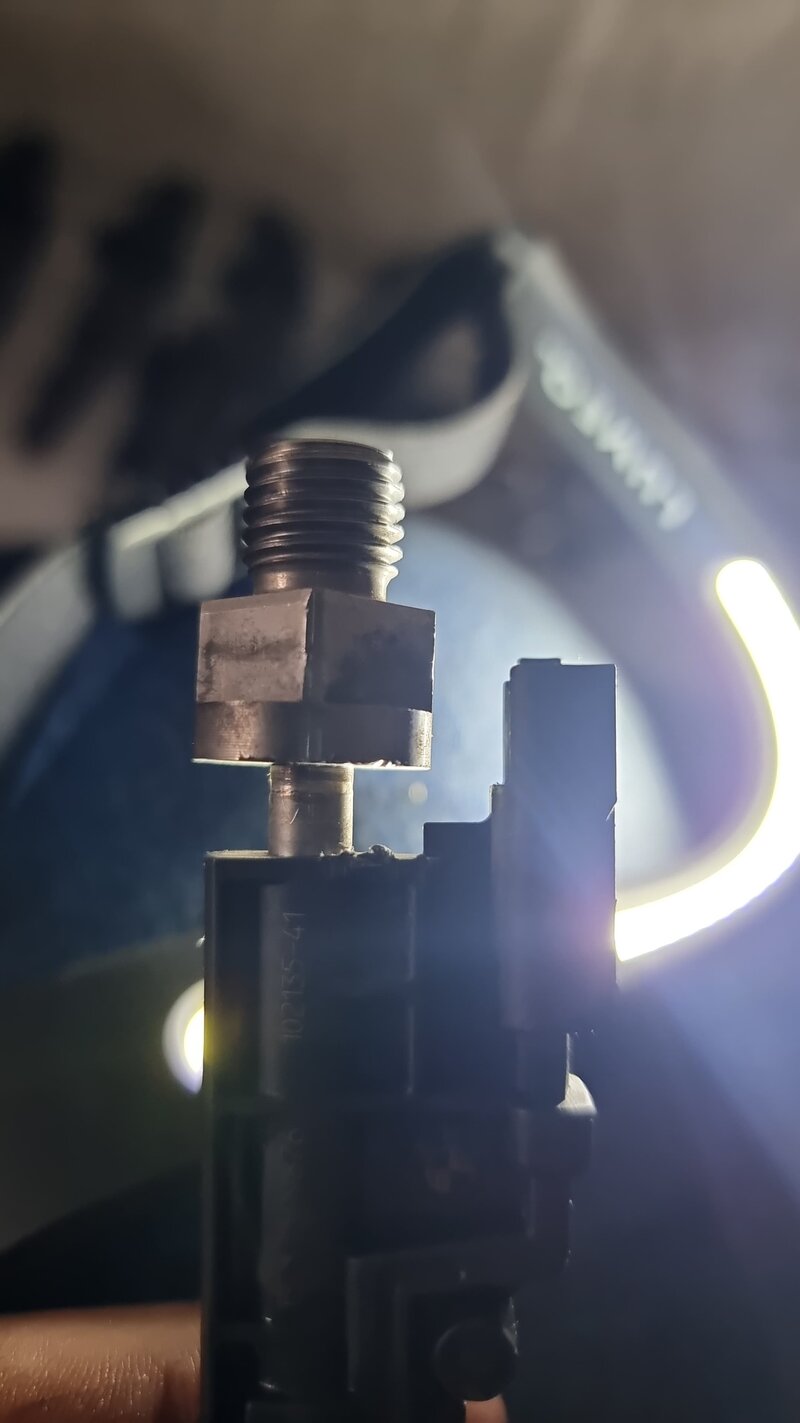

On removing the injector, i found the head to have been bent somehow, and a hairline crack, allowing fuel to leak.

With this, i had to now replace the injector, with mine being EU5 injectors needed, i called JSN, and the price per injector with my discount was R4875, i decided to call Goldwagen, and the same injector by them, was R1750, and as luck would have it, they had only 1 in stock, so i purchased that.

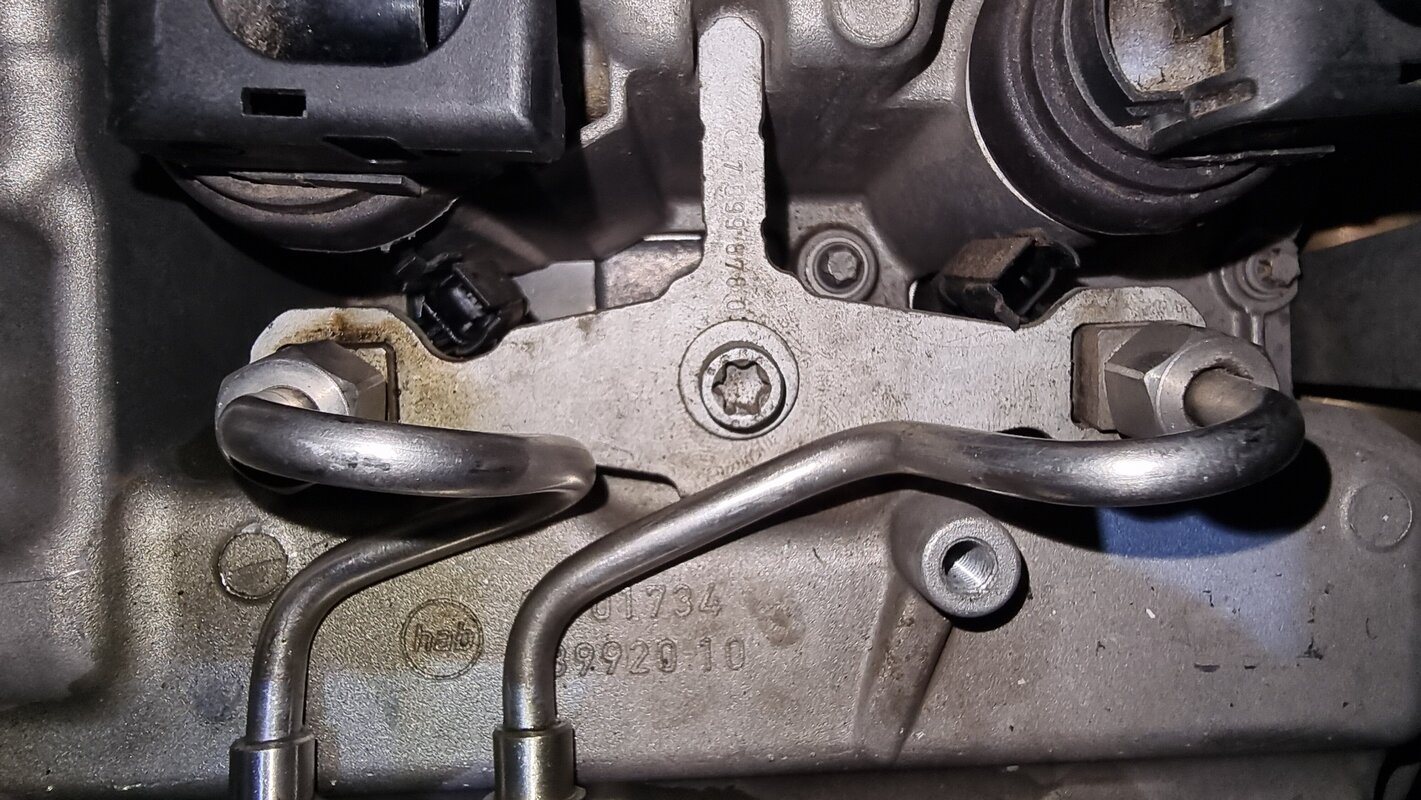

I went about removing all injectors, stripping off the old seals, 3 of the 8 injectors did not even have their Decoupler rings installed (I take this now as shoddy work from RM Autotech who rebuilt the motor, thanks Rapesh... More on this later.)

One of the injectors had a 2nd decoupler ring stuck in the head, which took me about 45min to remove carefully:

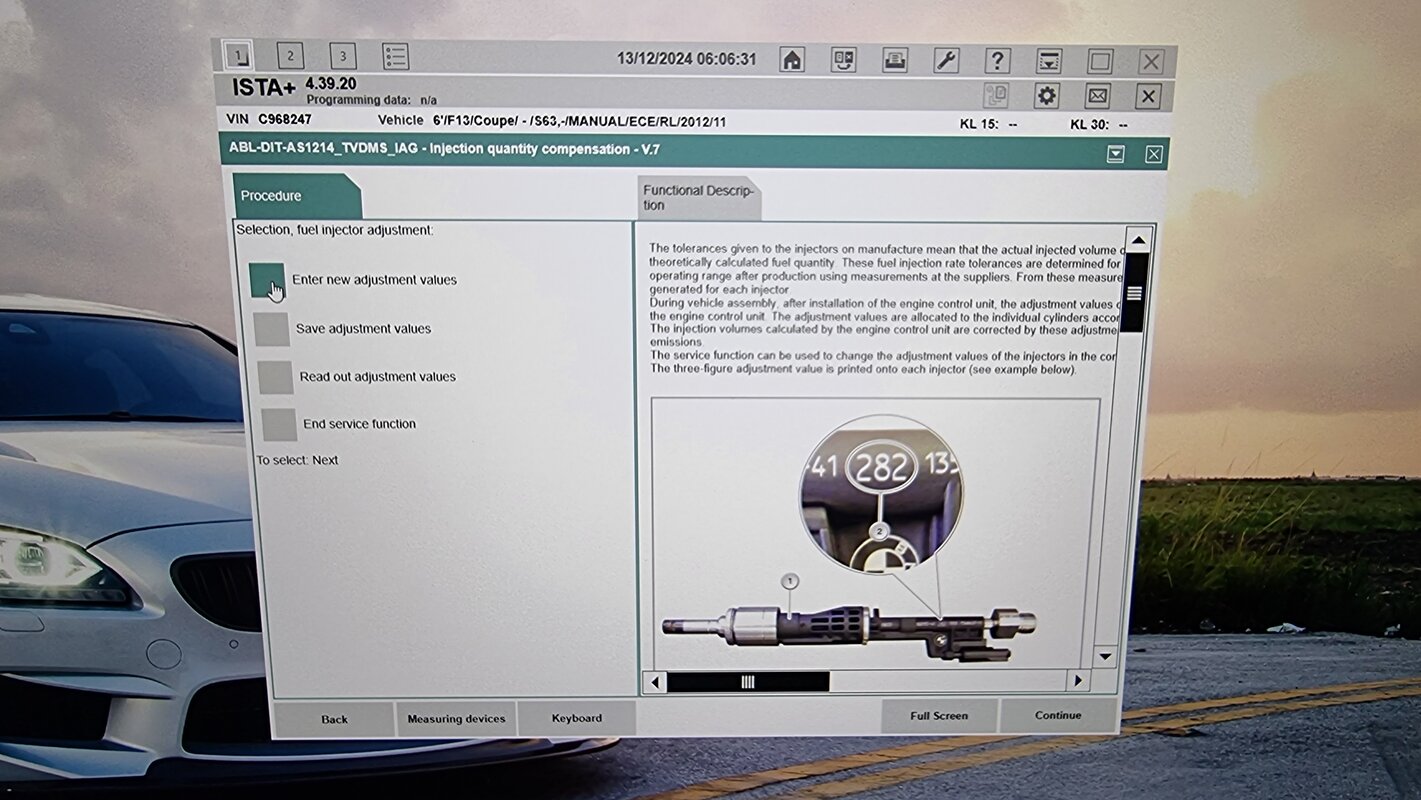

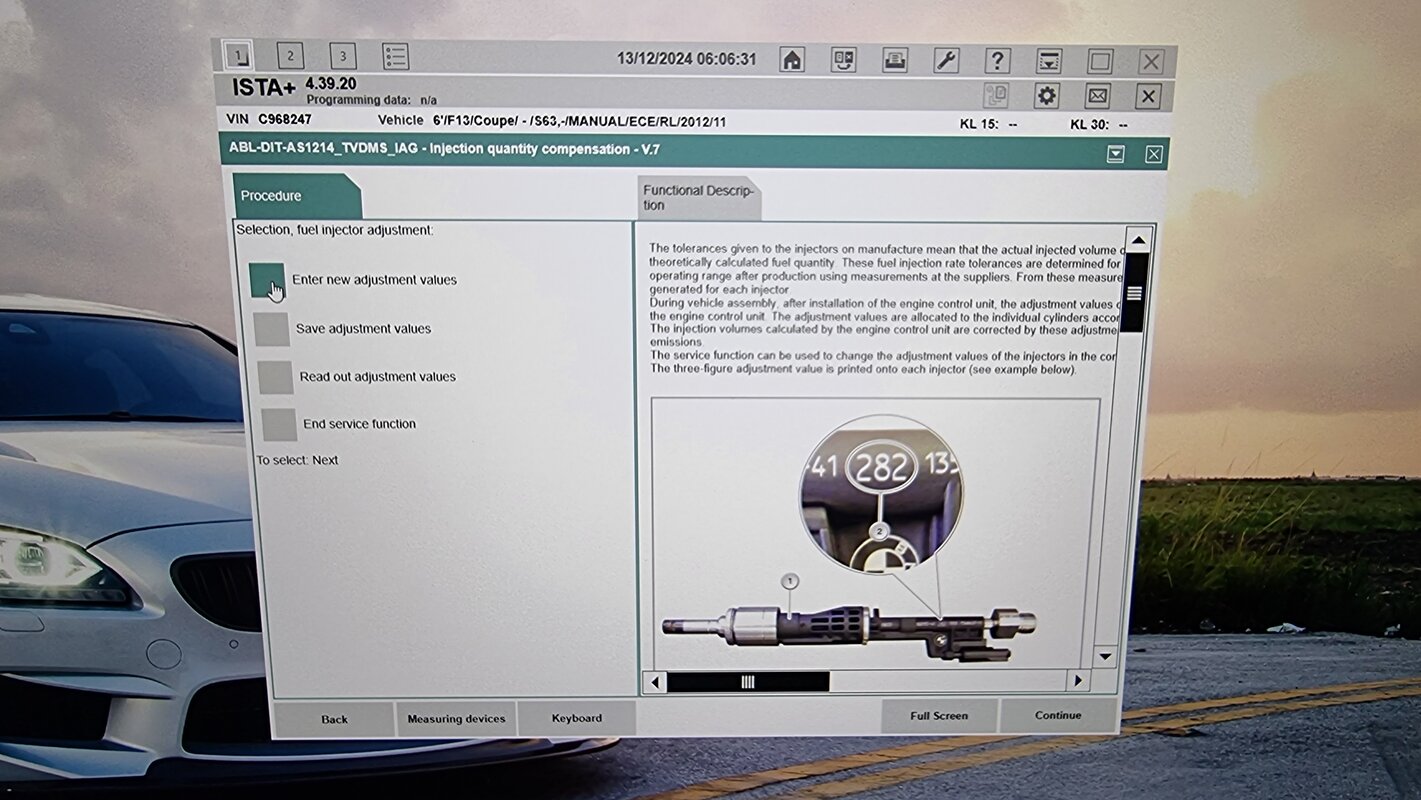

Eventually got everything put back together, injectors installed in the correct direction and orientation, decoupler rings and new seals installed. And each injectors numbers taken note of so i can code them in.

So i started with ISTA

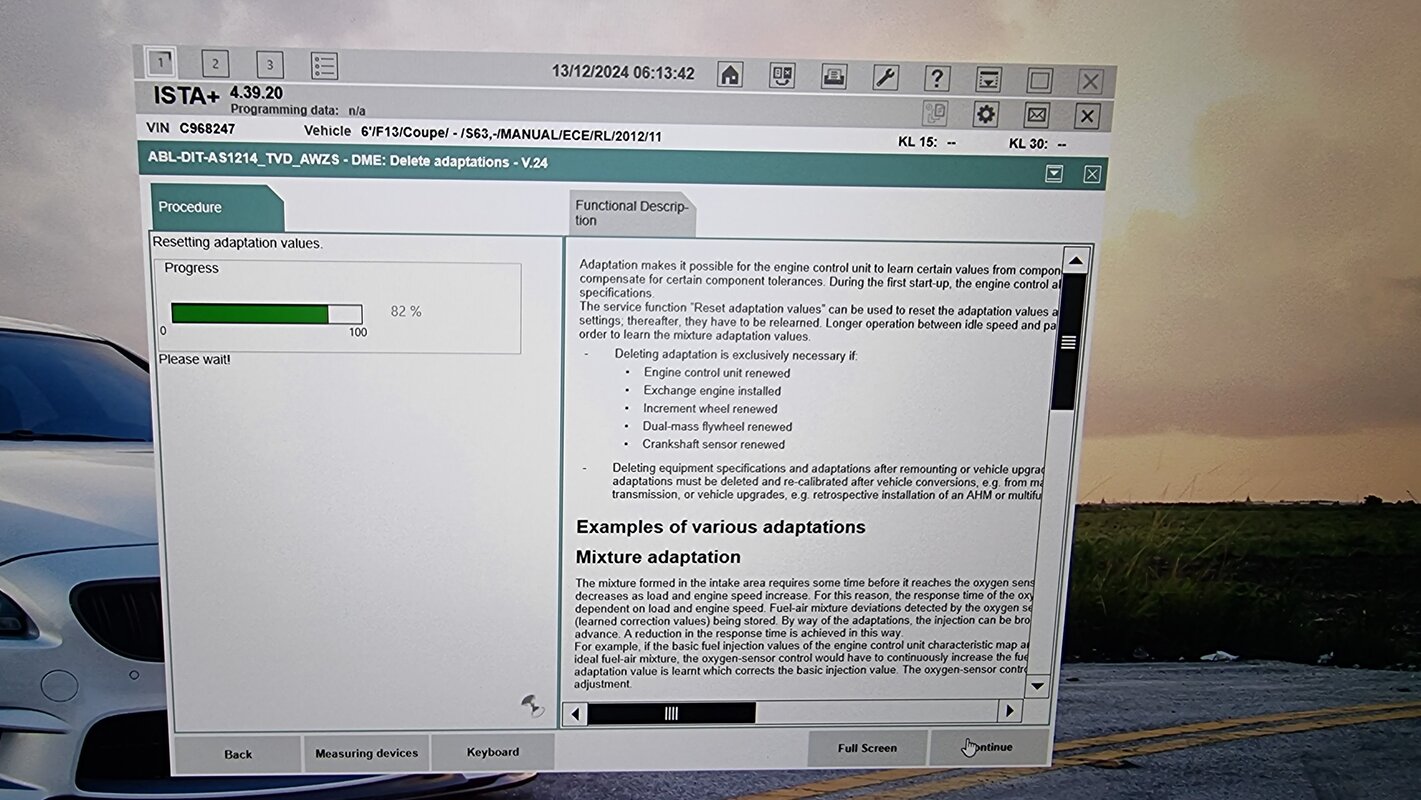

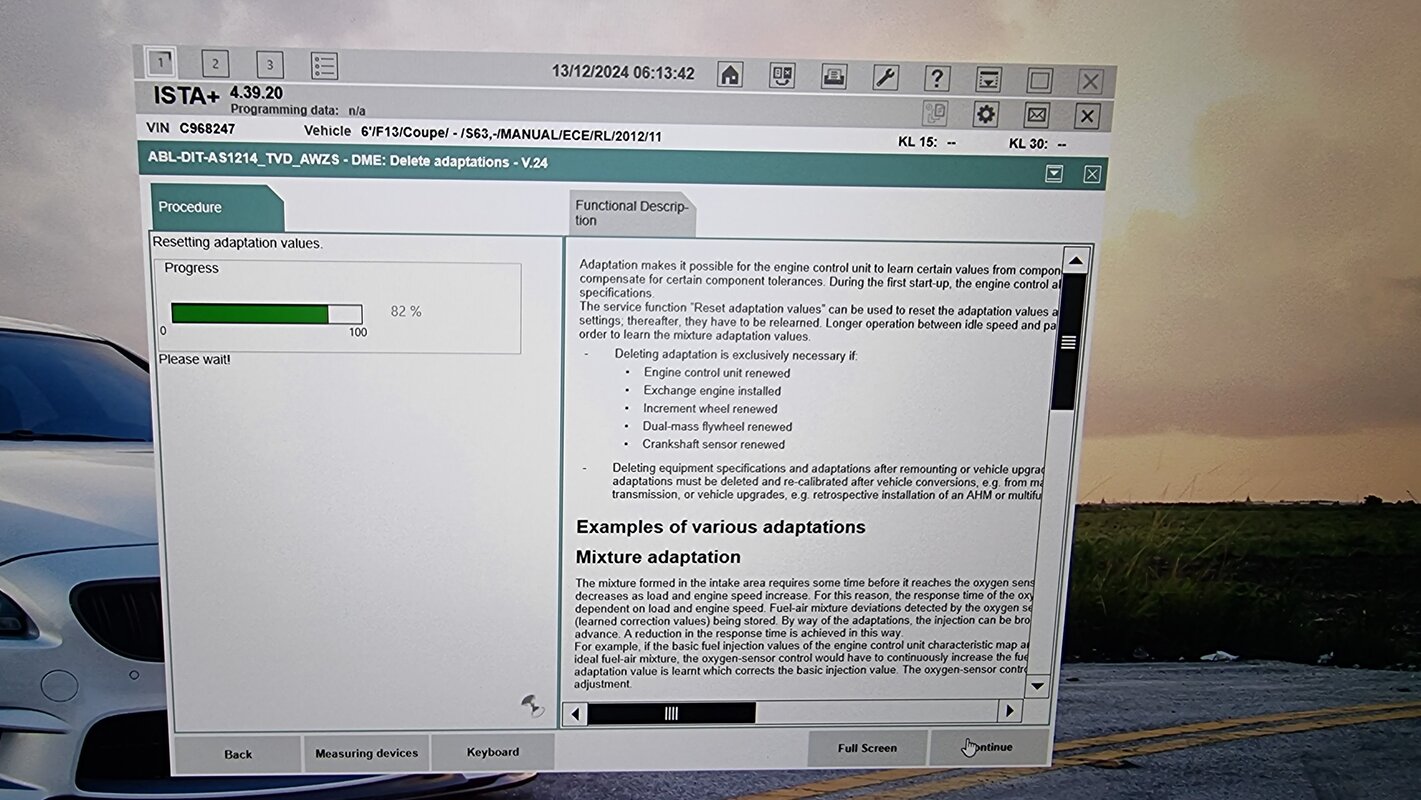

Once that was done, the guide i was following showed that the Delete Adaptations was to be run also, so that was my next step.

This was a HUGE mistake, after i ran all the procedures, i started the car up, and immediately got an error and the car ran badly and lumpy, initially i assume its for fuel pressure, so i shut it down, cleared codes without reading them, and started her up again, same thing.

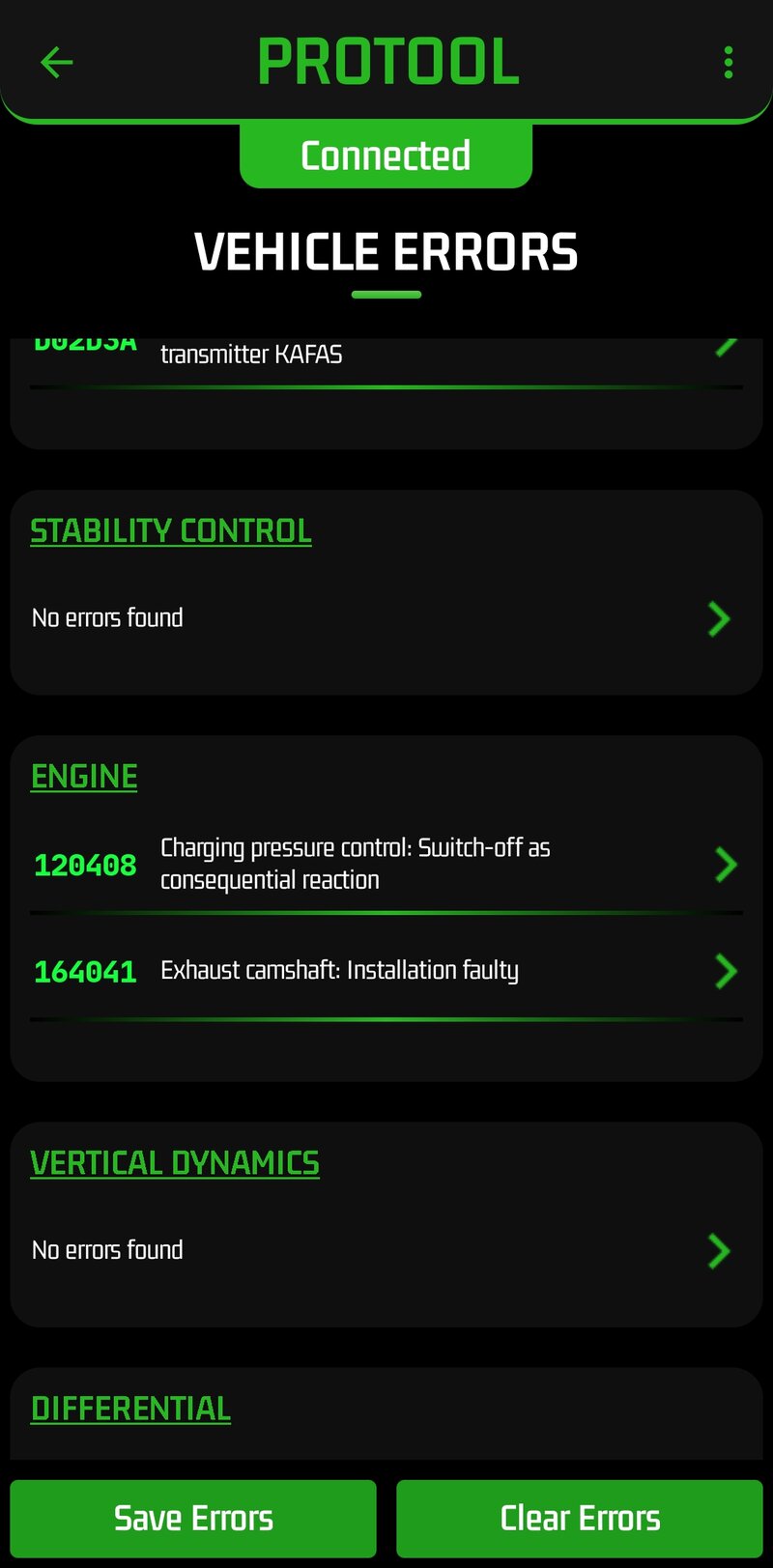

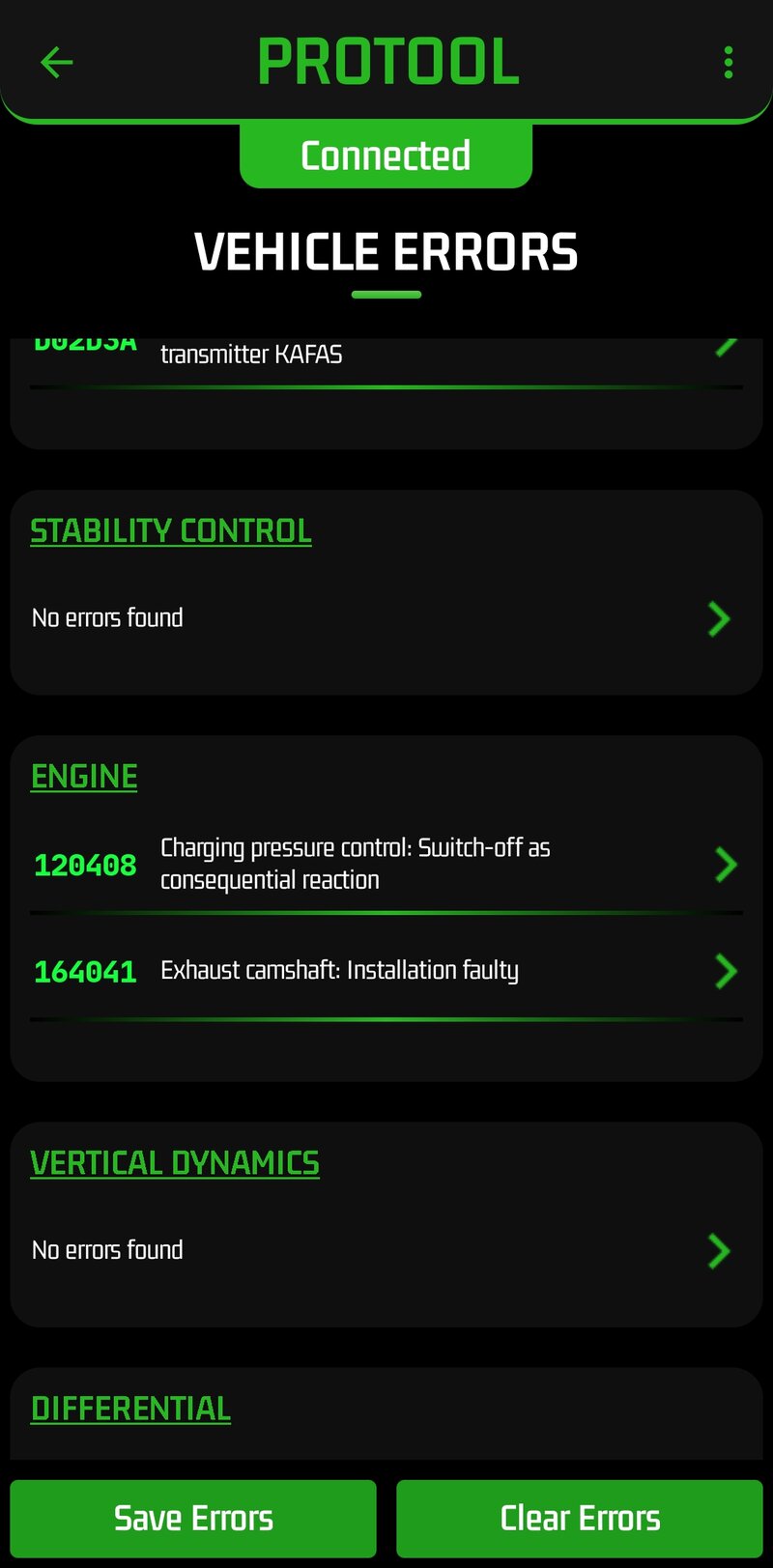

and this was the codes:

Turns out, the delete Adaptations had reset the timing (Dont ask me how), after trying EVERYTHING i could to fix it, i decided to strip the ECU's again and check electrical connections, thinking i may have bent a pin. but all was ok, and i had no broken wires, or bad connections.

So i connected everything again, and started the car.

And... car was perfect, ran fine, no issues, had boost, no errors.

Drove to JSN to drop off the tools, and speak to the Service Tech about the issue i encountered, when i got there, i switched off the car, and decided to start her up again to check, and low and behold, the error had returned, Camshaft Installation Faulty.

The tech said they have had this before after deleting adaptations, and no longer use the function in fear of this, as the only resolution was remove the valve covers, and manually time the car again with the special tool.

I thought this absolutely ludicrous, as how can this be caused electronically, but cannot be repaired electronically. Anyways, i limped home with the car, and she stayed in the garage, and i researched everything i could find on this error, i swapped Vanos units, swapped Camshaft position sensors, all to no avail, the error was always present, and always on the same bank.

More to come... ...