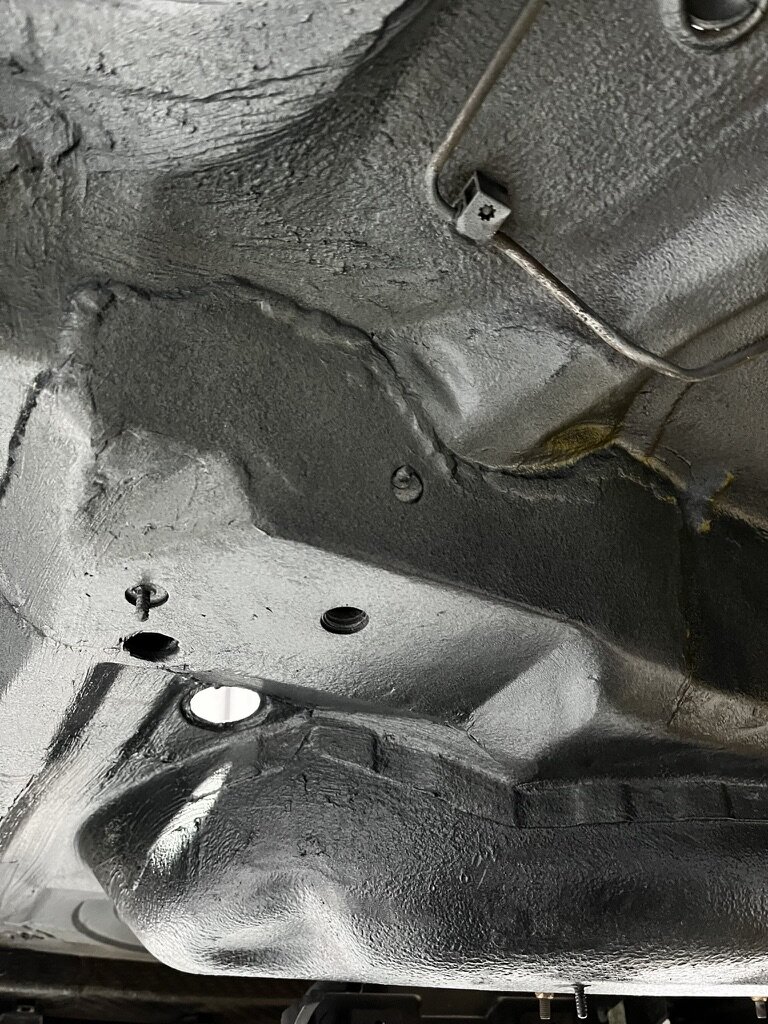

So, the situation was rescued (eventually) and then it was time for the car to come home. Oh wait, they forgot to paint & seam seal something, so that had to be done before it was time to come home. Safe to say that was one of the most stressful undertakings of my adult life, but came out of it with 75% of what I wanted, new relationships & a path forward for anyone looking to do this in the future. My initial considerations were either:

1. Get the job done at mechanic's shop - get them to strip the rear end, have the car on the lift for a while, hire a freelance welder (who'd be competent) and then figure out paint/seam sealing/cavity waxing on the fly, and then have the mechanic reassemble. Downsides were you'd need a shop with space & who'd be happy to have the car on the lift for say 2 weeks, but most importantly that the painting of the underside would be the potential weakest link in the job. But since SA has very moderate weather, and lots of M cars sleeping during winter, maybe this wouldn't be such a big deal. Also, we don't experience the corrosion that UK & US based cars do.

2. Get a body shop to do the entire job. They have mechanics right? Lifts? Check. Experienced welders? Sure, they don't stitch-weld race cars all day, but surely a competent in MiG/TiG operator? And they'd be able to dress the job the nicely once done, and rust surely wouldn't be a concern going forward into the future. Enjoy the car in the wet if you're so inclined.

I ended up going with option 2 because of fear and wanting to rely on someone experienced in the industry/task. But what I've learnt is Reddish Motorsport is not in South Africa, quality workmanship is hard to come by and similar to home renovations, you need to hire an expert for each phase of the job, if no expert exists for the entire project, and project manage it yourself. I should've known that an external person won't manage the entire project to your standards - you need to get involved.

So how I'd do it going forward is:

1. Get the car stripped by a mechanic, and have a trolley to be able to transport the car.

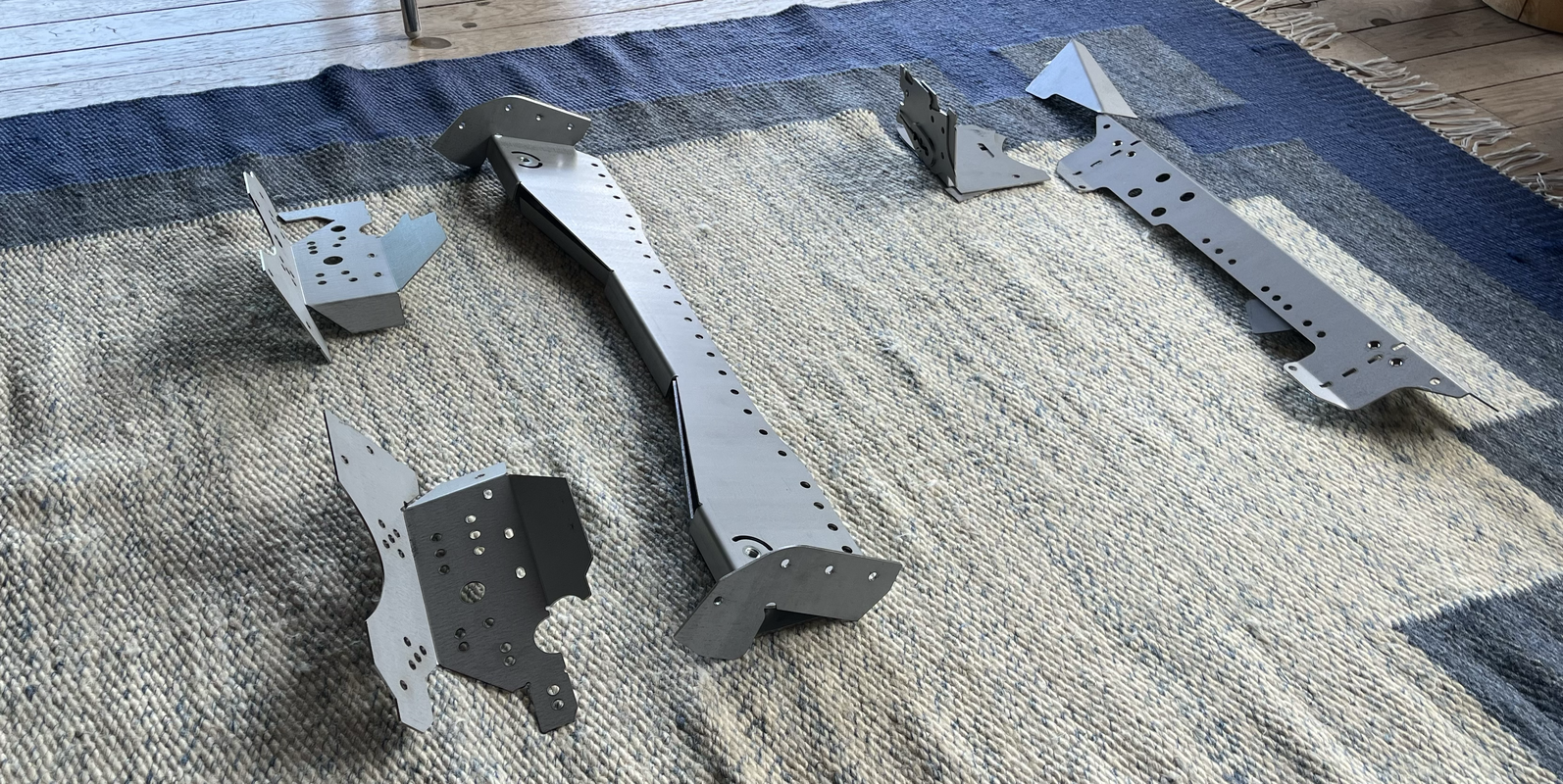

2. Get an experienced artisan in to do the metal work/fabrication.

3. Get the car off to a restoration-type body shop - think a body shop that focusses on classics/restorations.

4. Get the car back to the mechanic to reassemble.

This all sounds complicated, and it is. But if you have the right team/facilities lined up, it can be fairly straightforward. And completed to a sufficient level of detail, without having to install grey hairs or have your wallet extorted. The job is not

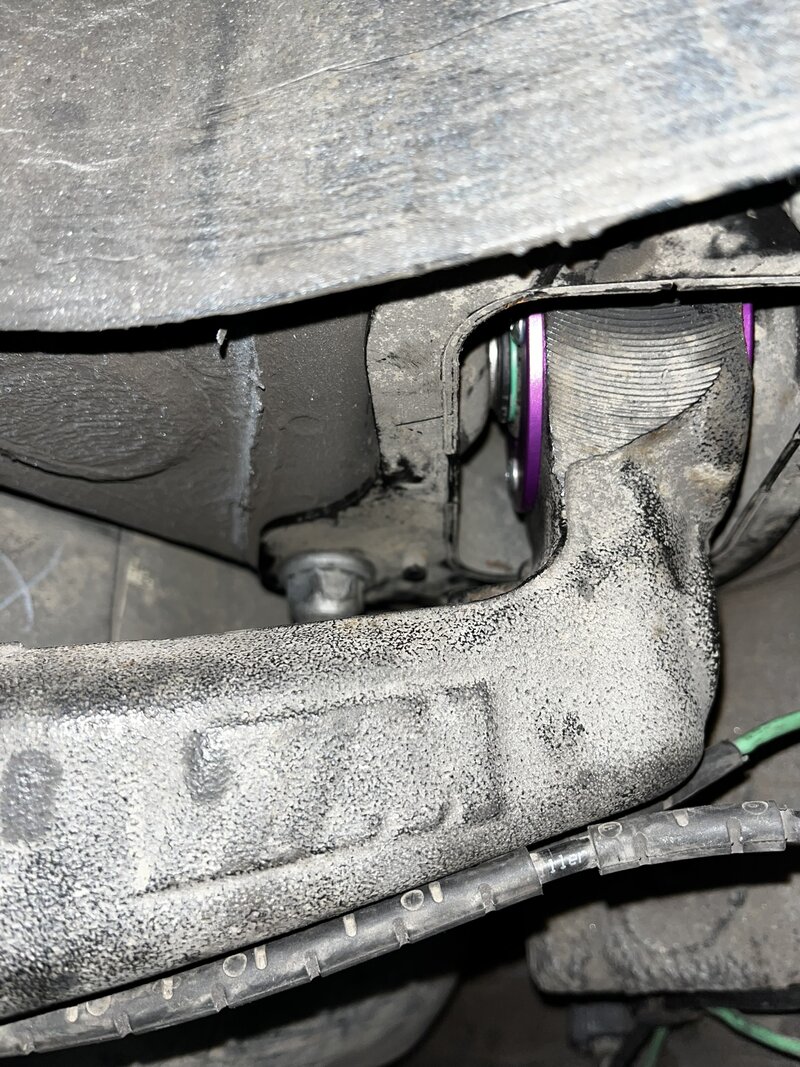

that complicated, there are just lots of moving parts and unknowns. Through the process I've learnt who these people are, where they're based and am keen to try this whole process again. TO THE LEVEL OF QUALITY I DEEM SATISFACTORY. I think I've learnt enough in this process to be able save someone a ton of headaches, money and get the job done right. Small things you know? Like BMW not selling E46 M3 rear diff mount bushings, only the entire cover with the bushes pre-installed at $260?!?! There is another BMW that uses the same bushes, which are available from Goldwagen and cost +-R600 for the pair. That solid/poly subframe bushes don't affect the NVH much, but that diff mount bushings do (since they can isolate the drive line shock/vibration from the car body). Where to look for cracks, what parts of the RACP repair is non-negotiable to get 100% right etc.

Oh, and cost you ask? This job cost me R36500, ex-vat - the ex-vat part I think this was the bodyshop trying to make amends and somehow give me a "discount". So that's R42k for other mortals, just for disassembly, metal work, paint & reassembly. When I showed the fabricator the car when it was still at the body shop and after we went through the CMP install instructions, his estimate was less than R10k for a weeks worth of (QUALITY) metal work. Then I'd want the entire underside of the car degreased & cleaned, plates seam sealed and blown over with fresh paint. I think we can get it done for less that I payed and at a much higher level of quality, with 1/10th of the stress for all parties. Also, nicely documented for the owner? I received 1 photo from the body shop. 1

Well, with all the new bushings and having the worry of the RACP falling out no longer being present, the first drive was a hoot. The rear end felt SO responsive, I was blown away. And wow, old tires are a hazardous. Just on the "relaxed" test drive (DSC off you say? Is that relaxed to you?) around the industrial park at the body shop, the car wanted to sideways & nearly bit me. She's got more torque than a M54 320i, that's for sure. But what a feeling!

Here she is, getting the first fill-up in a while (3 years?!?)